Metal Melting Rotary Furnaces

Metal Melting Rotary Furnaces Specification

- Product Type

- Metal Melting Rotary Furnaces

- Material

- Mild Steel

- Capacity

- Varies as per the Unit Ton/day

- Application

- Lead Recycling Plant

- Weight

- Varies as per the Unit Kilograms (kg)

- Dimension (L*W*H)

- Varies as per the Unit Millimeter (mm)

- Color

- Customized

Metal Melting Rotary Furnaces Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Others

- Supply Ability

- Set

- Delivery Time

- Months

- Packaging Details

- Export Worthy Packaging

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2008

About Metal Melting Rotary Furnaces

Metal Melting Rotary Furnaces

We are a renowned organization that is involved in manufacturing and supplying Rotary Furnaces. It is very flexible and universal equipment used for recycling many non-ferrous metals. Offered range generates high pollution both as flue gases & fugitive emissions. Moreover, we offer these Rotary Furnaces in various specifications at nominal rates.

Features:-

- Equipment scalable for installing higher capacities

- Recovers all lead in one production cycle

- Can be fired with various fuels

-

A lead production system based on this technology has certain distinct characteristics such as:

- Equipment scalable for installing higher capacities

- Recovers all lead in one production cycle

- Plates & powder from scrap battery as well as slag from Mini Blast Furnace can be used as raw material

- Requires addition of certain consumables

- Can be fired with various fuels

- Generates high Pollution both as Flue Gases & Fugitive Emissions

Specifications :-

| Outside dimensions of the Rotary | |

| Shell diameter | 2075 mm |

| Shell length | 2500 mm |

| Total length | 4500 mm |

| Charging diameter | 450 mm |

| Exhaust side diameter | 450 mm |

| Refractory thickness | 200 mm |

| Fuel | Furnace Oil |

| Burner | Model 4 A |

| FD Fan capacity | 1250 cmh at 1000 mm of WG |

| Gear Box in drive | 8 - 1:40 Ratio |

| Motor in drive | 15.0 HP x 960 RPM |

| Structure used for base | ISMC 250 x 80 |

Other Details:-

| Raw Material Charged | 3000 kgs / Batch |

| Total additive chemicals charged | 400-500 kgs / Batch |

| Rotational speed | 1-2 RPM |

| Fuel used | Furnace Oil |

| Calorific value of fuel used | 8600 kCal / kg. |

| Fuel consumed | 30-40 lt/ hr. |

| Air provided for process | 1250 cmh |

| Lead produced | 9000-10000 kg/day (for Raw Material feed of 12-15 TpD; |

| raw material being lead powder and plates) | |

| Flue gas generation | 15000 cmh |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lead Recycling Plant Category

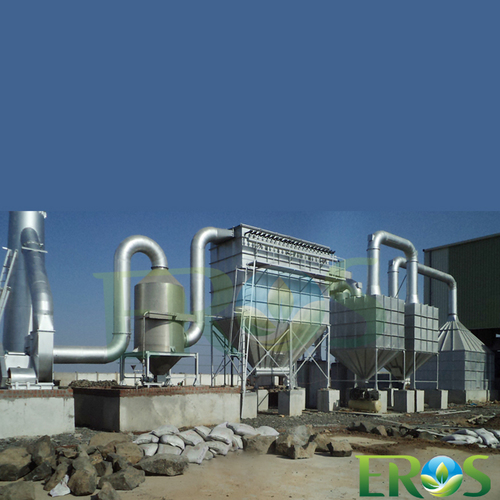

Fugitive Emission Control Systems

Price 1600000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Customized

Material : Mild Steel

Product Type : Fugitive Emission Control Systems

Battery Recycling Plant

Price 4500000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Mild Steel

Product Type : Battery Recycling Plants

Lead Oxide Ball Mill

Price 2500000 INR / Set

Minimum Order Quantity : 1 Set

Color : Silver

Material : Mild Steel

Product Type : Lead Oxide Ball Mill

Mini Blast Furnaces

Price 1100000 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Material : Mild Steel

Product Type : Mini Blast Furnaces

(Formerly Eros Consultant)

108-109, 1st Floor, Savitri Complex-1,

Dada Motors Building, Kalsi Nagar,

G.T. Road,

City - Ludhiana 141003

State - Punjab, Country - INDIA.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free